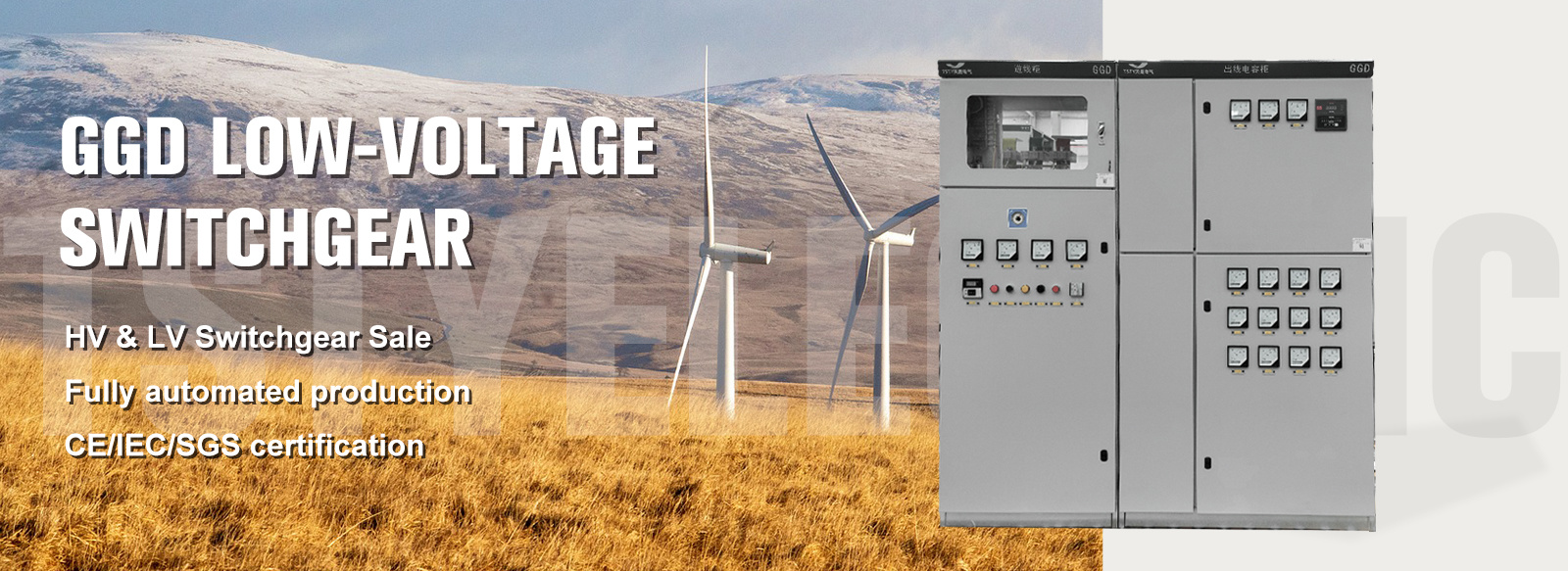

GGD Switchgear Series is primarily used in power plants, substations, and industrial/mining enterprises for 50-60Hz AC distribution systems, accommodating up to 4,000A rated current. Designed for energy conversion, distribution, and control in power/lighting systems.

Features: Excellent thermal stability, innovative structure, practical electrical schemes, strong universality, high protection level.

Technical Parameter

Technical Parameter| Model | Rated Voltage (V) | Rated Current (A) | Rated Short-circuit Breaking Current (KA) | Rated Short-time Tithstand Current (IS) (KA) | Rated Peak Tithstand Current (KA) | |

| GGD1 | 380 | A | 1000 | 15 | 15 | 30 |

| B | 600(630) | |||||

| C | 400 | |||||

| GGD2 | 380 | A | 155(1600) | 30 | 30 | 65 |

| B | 1000 | |||||

| C | 600 | |||||

| GGD3 | 380 | A | 3150 | 50 | 50 | 105 |

| B | 2500 | |||||

| C | 2000 | |||||

Structural Features

Structural Features1.According to the usage: Distribution cabinets, busbar couplers, feeder cabinets, motor control cabinets, reactive compensation cabinets, lighting distribution cabinets.

2.Internal Structure:

(1)316L stainless steel + nano-ceramic coating, passing 3,000-hour salt spray/200 thermal cycling tests.

(2)ZMJ-type busbar clamps: Heat-formed high-flame-retardant PPO material with modular design, high mechanical strength, and insulation.

(3)Schneider benchmark intelligent production line enables 70% reduced manual intervention, 30-minute cabinet production cycle, 30% capacity increase, full compliance with IEC/GB standards.

(4)Zinc-plated hinges connect doors to frames with rubber-edged seals for easy installation.

(5)Threaded grounding screws establish complete earth protection circuits.

(6)Removable top cover facilitates main busbar adjustment.

Precision Manufacturing System

Precision Manufacturing System1. Micron-level precision manufacturing

Equipped with ±0.1mm high-precision industrial robots, it realizes millimeter-level control of switch cabinet bending and assembly, with a standardization rate of parts ≥99% and a size qualification rate of over 99.5%.

2. German imported spraying system

Adopting electrostatic spray guns and water-based environmentally friendly paint, the coating uniformity error is ≤5μm, VOC emissions are reduced by 80%, and "zero-defect appearance" and green manufacturing are achieved simultaneously. The spraying defect rate is controlled within 0.3%.

3. Fully automated production

Relying on Schneider's benchmark intelligent production line, a fully automated production model is created, manual intervention is reduced by 70%, the production cycle of a single cabinet is compressed to 30 minutes, and the production capacity is increased by 30%.

Core Advantages Of Digital Production Lines

Core Advantages Of Digital Production Lines1. Using the dual engines of "data + intelligence" to drive manufacturing innovation and build an industry-leading digital production system.

2. Relying on 220+ sets of intelligent equipment clusters, unmanned operation of the entire process from sheet metal processing to finished product assembly is realized, the manual intervention rate of key processes is less than 5%, and the yield rate exceeds 99.8%.

3. The U-shaped layout and modular design increase material handling efficiency by 40%, produce 10,000 high and low voltage equipment each year, and shorten the order delivery cycle by 30%.

4. AGV logistics and digital twin systems are linked to achieve 72 hours of unmanned continuous operation, and the capacity utilization rate reaches more than 95%. 5. Green manufacturing, waste recovery rate exceeds 90%, noise and emission indicators are 20% better than the national standard, and it has been rated as a provincial smart factory benchmark.

TSTY R&D Advantages

TSTY R&D AdvantagesTSTY currently has 600 employees and a technical R&D team of more than 200 people. It has established a science and technology innovation center to focus on material and process innovation and realize independent research and development of transformers; relying on the national CNAS certified laboratory, each product passes more than ten rigorous tests such as lightning strike and insulation no-load loss to ensure stable operation in the whole environment.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.