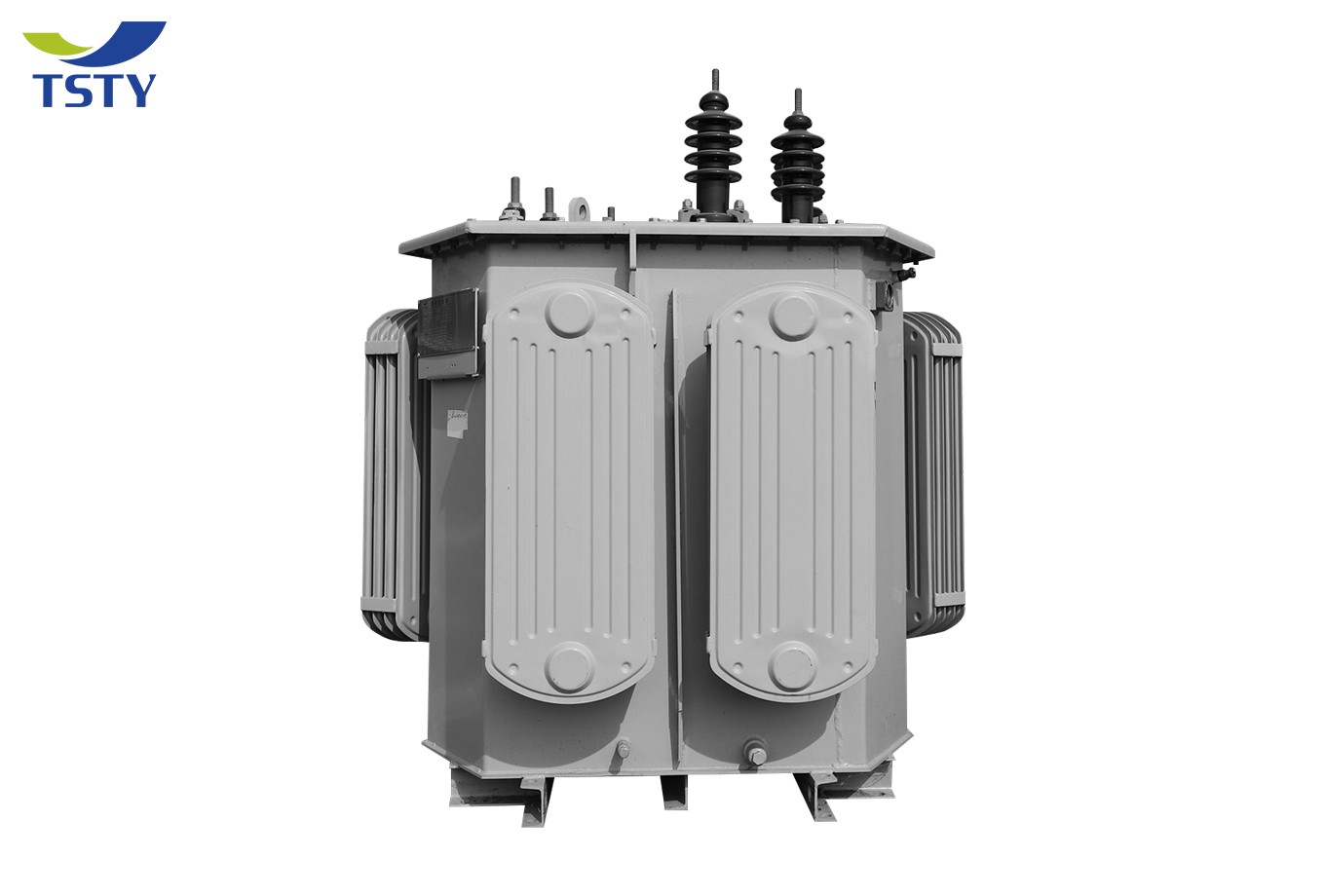

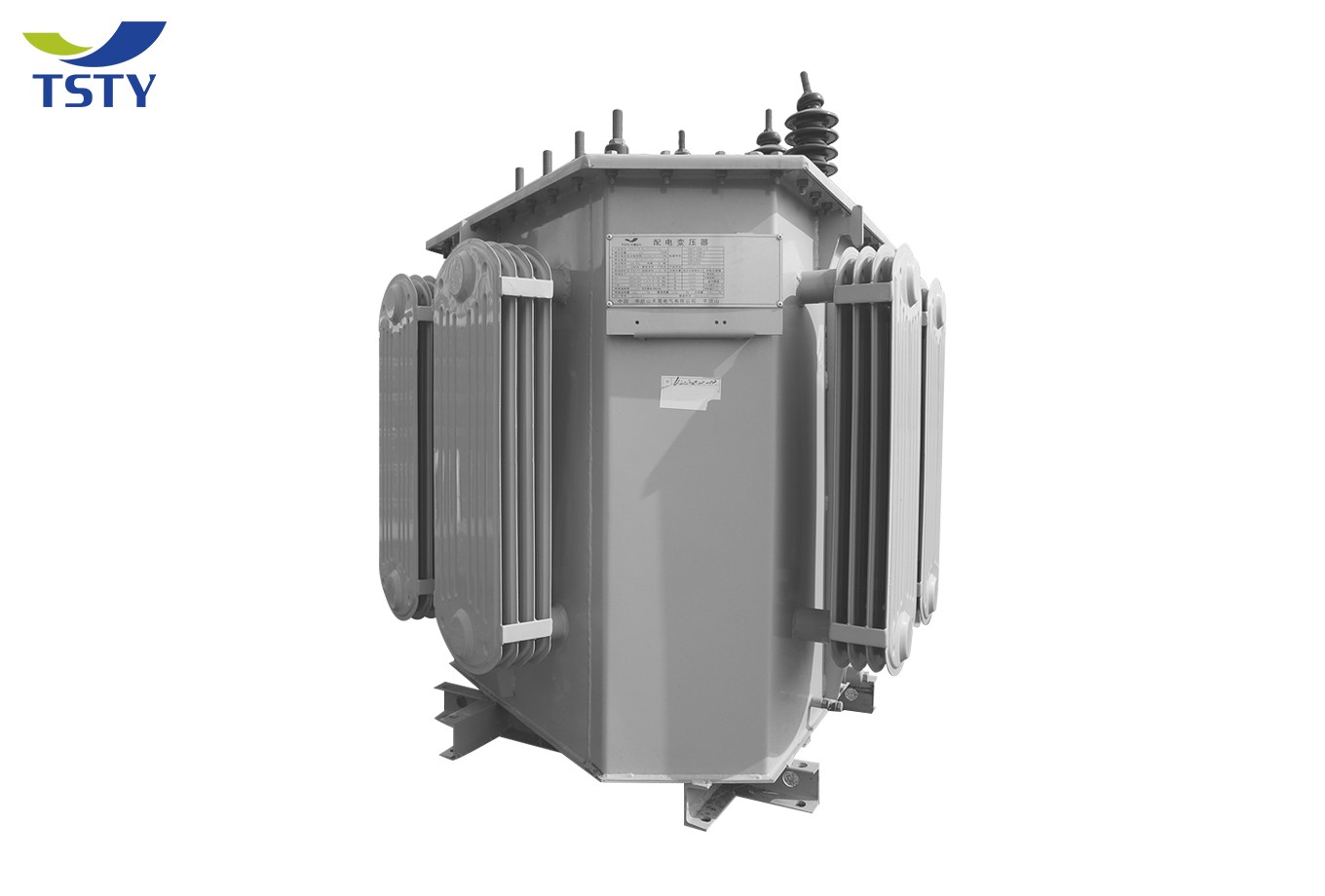

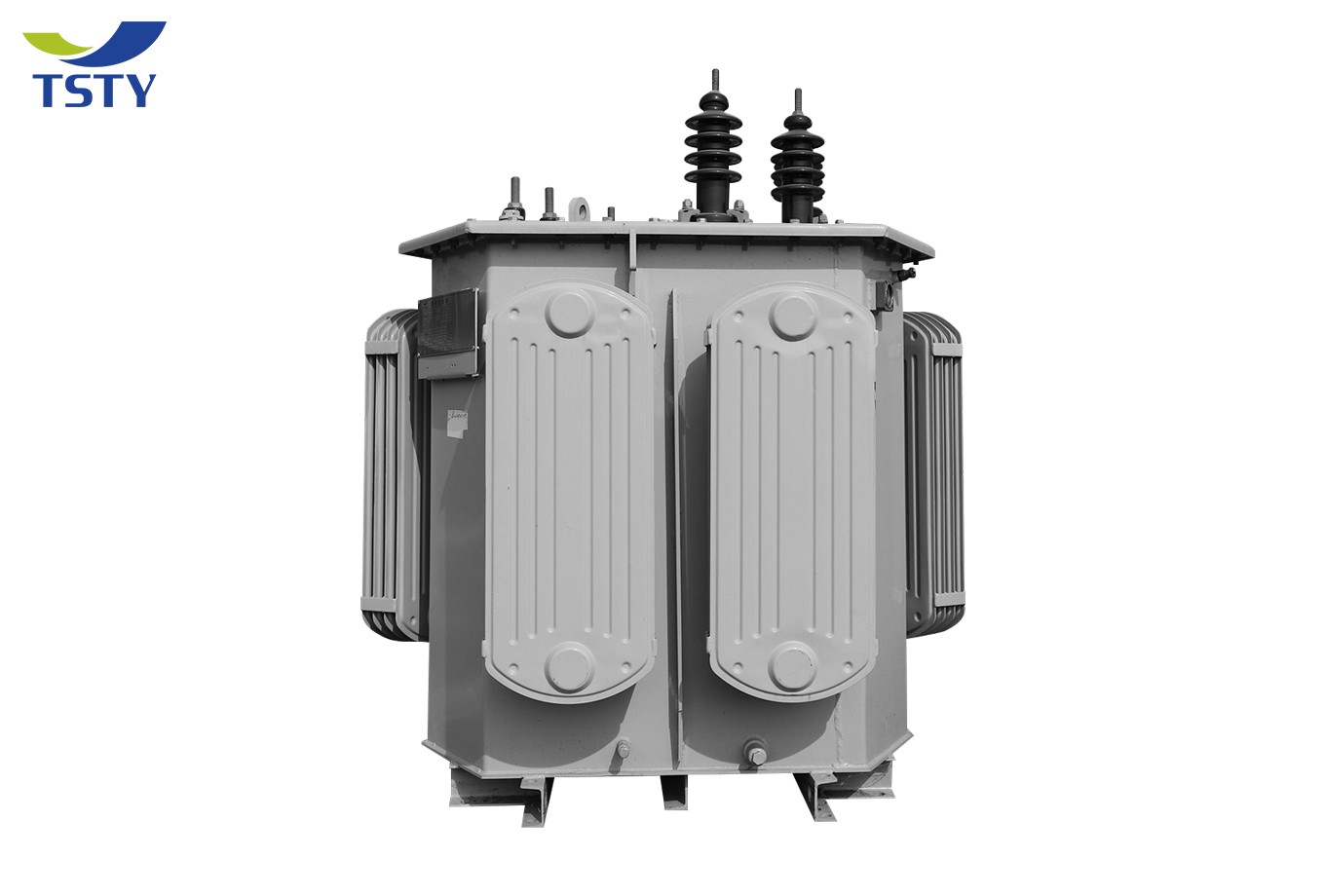

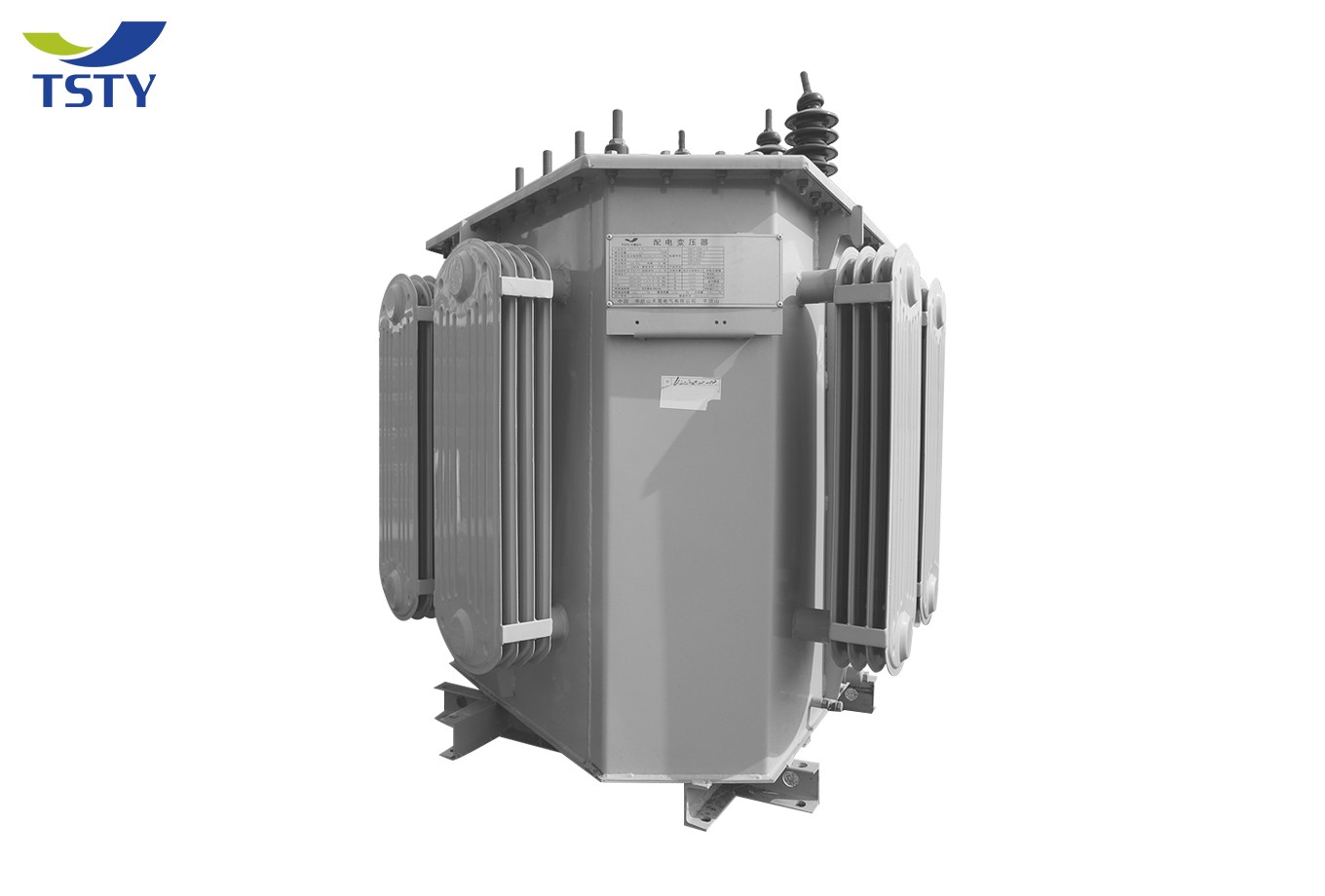

Brand Name: TSTY

Model Number: S(B)H

Phase: Three

Service Voltage: 6-11kV

Rated Capacity: 15-31500kVA

Amorphous alloy transformer is a low-loss and high-efficiency power transformer with iron-based amorphous metal as the iron core. The iron loss (ie no-load loss) of amorphous alloy transformers is 70-80% lower than that traditional transformers which generally use silicon steel as the iron core. It is an ideal low-loss energy-saving transformer at present. Because of low losses amorphous alloy transformers generate less heat .The temperature rise is low and the running performance will be very stable.

Parameters Table

| Type | Rated capacity | Connection symbol | Voltage combination | Losses(W) | No- load current (%) | Short-circuit impedance | Weight(kg) | |||

| (KVA) | (KV) | (%) | ||||||||

| H.V | Tapping | L.V | No-load | Load | ||||||

| range | ||||||||||

| SH15-M | 30 | Yyn0 |

6 11 |

±5% or ±2X2.5% | 0.4 | 30 | 600 | 1.7 | 4 | 340 |

| SH15-M | 50 | 43 | 870 | 1.3 | 430 | |||||

| SH15-M | 63 | 50 | 1040 | 1.2 | 560 | |||||

| SH15-M | 80 | 60 | 1250 | 1.1 | 720 | |||||

| SH15-M | 100 | 75 | 1500 | 1 | 830 | |||||

| SH15-M | 125 | 85 | 1800 | 0.9 | 940 | |||||

| SH15-M | 160 | 100 | 2200 | 0.7 | 1250 | |||||

| SH15-M | 200 | 120 | 2600 | 0.7 | 1450 | |||||

| SH15-M | 250 | 140 | 3050 | 0.7 | 1600 | |||||

| SH15-M | 315 | 170 | 3650 | 0.5 | 1980 | |||||

| SH15-M | 400 | 200 | 4300 | 0.5 | 2300 | |||||

| SH15-M | 500 | 240 | 5150 | 0.5 | 2570 | |||||

| SH15-M | 630 | Yyn0 or | 320 | 6200 | 0.3 | 6 | 2550 | |||

| SH15-M | 800 | Dyn11 | 380 | 7500 | 0.3 | 2810 | ||||

| SH15-M | 1000 | 450 | 10300 | 0.3 | 3210 | |||||

| SH15-M | 1250 | 530 | 12000 | 0.2 | 3400 | |||||

| SH15-M | 1600 | 630 | 14500 | 0.2 | 4150 | |||||

| SH15-M | 2000 | 720 | 15535 | 0.2 | 5600 | |||||

| SH15-M | 2500 | 800 | 17270 | 0.1 | 6300 | |||||

Application:

It can be widely used in high-rise buildings, commercial centers, subways, airport, stations, industrial and mining enterprises, drilling platforms, oil production platforms; especially suitable for flammable, explosive and other places with high anti-inflammatory requirements and harsh environments, and can also be used in residential areas , Commercial streets, industrial and mining enterprises and rural power and lighting.

Indoor or outdoor where the altitude does not exceed 1000m;

Maximum ambient temperature +40℃;

Maximum daily average temperature +30℃;

The highest annual average temperature is +20℃, and the lowest temperature is -25℃.

Transformers that operate under special conditions of use can be provided according to user requirements.

Structural advantages:

1. The transformer core adopts a quasi-circular cross-section, which has a simple structure, improves the magnetic circuit distribution, and reduces no-load losses. Compared with the traditional long design, the short-circuit resistance is greatly enhanced, which increases the service life of the product.

2. The transformer core clamping parts are made of high-density electrical grade laminated wood, and the overall structure is more compact, which has a certain inhibitory effect on the stray loss caused by the leakage magnetic field.

3. By changing the internal body positioning and switch installation method, the high-voltage lifting platform is redesigned as a hand-hole-free structure to reduce the risk of oil leakage.

Production Ability

TSTY oil-immersed transformer production equipment is fully automated, with a daily production capacity of 50 units (efficiency increased by 3 times), which can meet the large-volume needs of distributors, the State Grid, etc.

Our Service

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.