Brand Name: TSTY

Model Number: SCB11、SCB13、SCB14

Phase: Three

Service Voltage: 6.6-35kV

Rated Capacity: 30-5000kVA

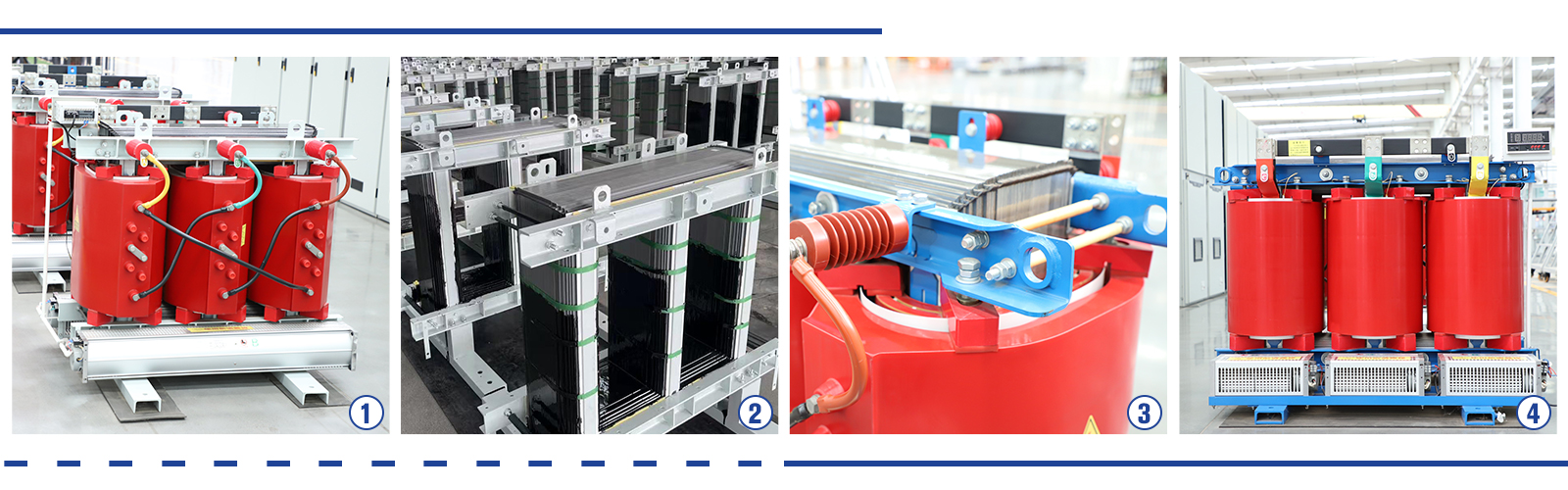

11kv/33kv dry-type transformers are widely used in medium voltage power distribution systems. 11kv transformers are usually used for urban power distribution, and 33kv are used for industrial high voltage. Due to the advantages of oil-free fire prevention, low loss, and green environmental protection, dry-type transformers are widely used in high-rise buildings, underground substations, data centers and other places with strict fire protection requirements.

11kv/33kv Parameters

11kv/33kv Parameters

| Model | Rated capacity (KVA) | Connection symbol | Voltage combination (KV) | No-load loss (W) | Load loss (W) | No-load current (%) | Short circuit impedance (%) | ||

|

High- voltage |

Tapping range |

Low- voltage |

|||||||

| SC10-30 | 30 |

Yyn0 or Dyn11 |

11 10.5 10 6.3 6 |

±5% ±2×2.5% |

0.4 | 190 | 710 | 2.4 | 4.0 |

| SC10-50 | 50 | 270 | 1000 | 2.4 | |||||

| SC10-80 | 80 | 370 | 1380 | 1.8 | |||||

| SC10-100 | 100 | 400 | 1570 | 1.8 | |||||

| SC10-125 | 125 | 470 | 1850 | 1.6 | |||||

| SCB10-160 | 160 | 550 | 2130 | 1.6 | |||||

| SCB10-200 | 200 | 630 | 2530 | 1.4 | |||||

| SCB10-250 | 250 | 720 | 2760 | 1.4 | |||||

| SCB10-315 | 315 | 880 | 3470 | 1.2 | |||||

| SCB10-400 | 400 | 980 | 3990 | 1.2 | |||||

| SCB10-500 | 500 | 1160 | 4880 | 1.2 | |||||

| SCB10-630 | 630 | 1350 | 5880 | 1.0 | |||||

| SCB10-630 | 630 | 1300 | 5960 | 1.0 | 6.0 | ||||

| SCB10-800 | 800 | 1520 | 6960 | 1.0 | |||||

| SCB10-1000 | 1000 | 1770 | 8130 | 1.0 | |||||

| SCB10-1250 | 1250 | 2090 | 9690 | 1.0 | |||||

| SCB10-1600 | 1600 | 2450 | 11730 | 1.0 | |||||

| SCB10-2000 | 2000 | 3050 | 14450 | 0.8 | |||||

| SCB10-2500 | 2500 | 3600 | 17170 | 0.8 | |||||

| SCB10-1600 | 1600 | 2450 | 12900 | 1.0 |

8.0 |

||||

| SCB10-2000 | 2000 | 3050 | 15890 | 0.8 | |||||

| SCB10-2500 | 2500 | 3600 | 18890 | 0.8 | |||||

Main performance parameters 35KV voltage regulating power transformer without excitation.

| Model | Connection symbol | Voltage combination (KV) | No-load loss (W) | Load loss (W) | No-load current (%) | Short circuit impedance (%) | ||

|

High- voltage |

Tapping range |

Low- voltage |

||||||

| SC10-800 |

Dyn11 Yd11 Yyn0 |

33~38.5 |

±5% ±2×2.5% |

3.5 6 6.3 10 10.5 11 |

2200 | 9400 | 1.1 | 6.0 |

| SC10-1000 | 2610 | 10800 | 1.1 | |||||

| SC10-1250 | 3060 | 11900 | 1.0 | |||||

| SC10-1500 | 3600 | 15400 | 1.0 | |||||

| SC10-2000 | 4130 | 18200 | 0.9 | 7.0 | ||||

| SC10-2500 | 4750 | 21800 | 0.9 | |||||

| SC10-3150 | 5880 | 24500 | 0.8 | 8.0 | ||||

| SC10-4000 | 6860 | 29400 | 0.8 | |||||

| SC10-5000 | 8180 | 34960 | 0.7 | |||||

| SC10-6300 | 9680 | 40800 | 0.7 | |||||

| SC10-8000 |

Dyn11 Yd11 YNd11 |

11000 | 46060 | 0.6 | 9.0 | |||

| SC10-10000 |

6 6.3 10.5 11 |

12660 | 56500 | 0.6 | ||||

| SC10-12500 | 15400 | 64600 | 0.5 | |||||

| SC10-16000 | 18900 | 76000 | 0.5 | |||||

| SC10-20000 | 22400 | 85500 | 0.4 | 10.0 | ||||

Product Advantage

Product Advantage1. The most advanced epoxy resin casting process in China is adopted, which has good insulation performance;

2. The new cold-pressed oriented silicon steel sheet is used as the iron core, and the seven-step 45-degree full-bevel joint has beautiful craftsmanship, and the no-load loss is reduced by 3-5% percentage points compared with the three-step;

3. In the traditional dry-type transformer production, the insulating paint of the iron core is mostly black or black, while TSTY uses transparent insulating paint, which can intuitively see the process and materials.

4. The core bending clamp is designed independently, with a simple structure, convenient manufacturing and installation, and greatly reduced operating noise.

R&D Advantages

R&D Advantages

TSTY currently has 600 employees and a technical R&D team of more than 200 people. It has established a science and technology innovation center to focus on material and process innovation and realize independent research and development of transformers; relying on the national CNAS certified laboratory, each product passes more than ten rigorous tests such as lightning strike and insulation no-load loss to ensure stable operation in the whole environment.

Project Case

Project CaseTSTY products are exported to more than 80 countries and regions, serving power projects in various regions.

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.