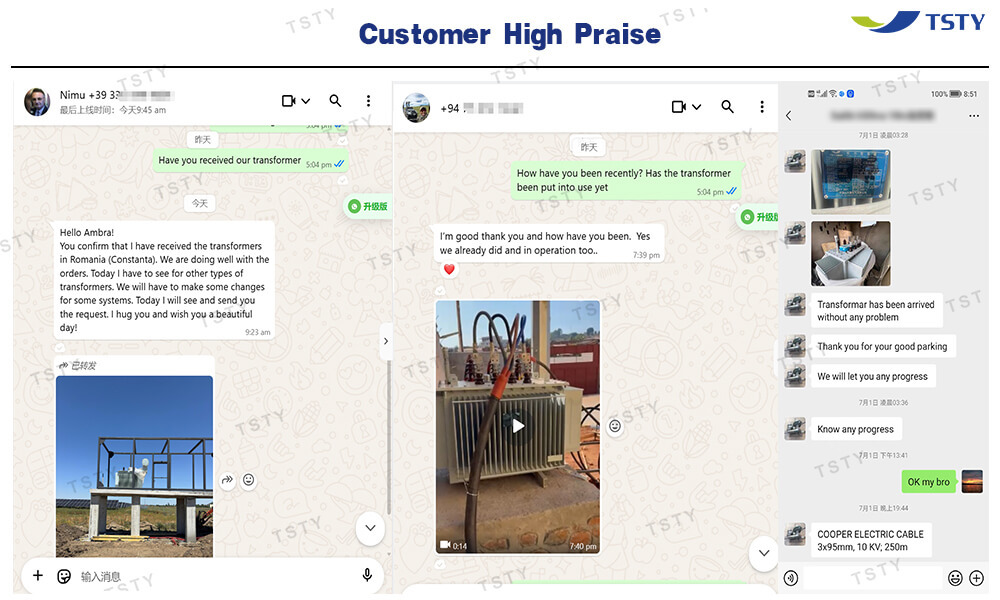

Why Does TSTY Receive So Many Positive Reviews?

Recently, TSTY received feedback from Romanian customers. After receiving the transformer, the Romanian customer installed and used the transformer under the guidance of local electricians and TSTY technology. Customer feedback said that the equipment worked well and there were no problems during use. In addition, TSTY has received wide acclaim from other customers.

Why do TSTY transformers receive so many good reviews?

The quality of the transformer is directly related to the safety and efficiency of the power system. Why do TSTY transformers receive so much praise from customers? TSTY's transformers cover design, manufacturing, materials, testing and other aspects to reflect the quality of TSTY transformers for you.

✅Core indicators

1. Loss indicators

No-load loss (iron loss): High-quality transformers use high-magnetic silicon steel sheets (such as 30ZH120) or amorphous alloys, and the no-load loss is more than 15% lower than the national standard.

Load loss (copper loss): oxygen-free copper winding (resistivity ≤ 0.017241 Ω·mm²/m) is used, and the load loss is reduced by 10% compared with ordinary copper wire.

Example: S11 type 315kVA no-load loss ≤ 720W (national standard S11 requires ≤ 850W).

2. Insulation level

Power frequency withstand voltage: 70kV/1min without breakdown on the high-voltage side of 35kV level.

Impact withstand voltage: 170kV full-wave lightning impulse test passed.

✅Materials and processes

In terms of materials, TSTY uses high-magnetic silicon steel such as Baosteel/Wuhan Iron and Steel as the raw material for the core, which has excellent magnetic properties and low iron loss. The lamination process adopts step lamination, which has the advantages of reducing loss, reducing noise, improving efficiency, and saving materials compared with the traditional lamination process.

✅Structural design

Box: Use national standard high-quality steel plate profiles, mechanical strength ≥ 345MPa, and durability life > 30 years.

The fully sealed structure effectively prevents the contact between insulating oil and air, avoids moisture and deterioration of insulation, and thus improves the overall performance and service life of the transformer.

Overload resistance: 120% load continuous operation for 8 hours, hot spot temperature ≤140℃ (limit 150℃).

✅Experimental verification and testing

TSTY has a national CNAS certified laboratory. Each transformer passes more than ten rigorous tests such as lightning impulse, temperature rise, and insulation no-load loss before leaving the factory to ensure stable operation in all environments. All products have passed CE, IEC, SGS, BV, GOST and other certifications, demonstrating professional capabilities and international credibility.